| With Gröning, the textile industry came to mesum in 1871 | ||

|---|---|---|

| 2021 | Completion of the new laboratory and R&D centre. Registration of the „G-Flowpack“ trademark. | |

| 2020 |

Certification BRC Global Standard for packaging materials.

Further development of coextrusion (5 layer) and converting

for tubular films. Opening of the „Wilhelm Gröning Forum“ as a training and event centre. | |

| 2018 | Further investments in machines and buildings as well as strategic developments in the plastic sector.

New company logo with the slogan „passion for quality film“. | |

| 2017 | In May, a large fire destroyed the equipment and confection of our glass fibre production. After more than 145 years of successful market presence in the sector of technical fabrics, in October, we completely closed the textile sector. | |

| 2016 | Further development of coextrusion and starting with barrier films of up to 7 layers.

Expansion of the laboratory towards film analytics. | |

| 2014 | Implementation of the energy management system DIN EN ISO 50001:2011. | |

| 2013 | Completion and opening of the new logistic and recycling centre. Extension of printing operations, installation of a 10-colour flexographic printing press. | |

| 2011 | DFTA Award for excellent flexographic printing in the category of large packaging. Celebration of the company's 140th anniversary. | |

| 2010 | Integration of the Gröningstraße to the premises. | |

| 2009 | DIN EN 15593 certification. „Management of hygiene in the production of packaging for foodstuffs“.DIN EN ISO 9001:2008 certification. „Quality Management System“. | |

| 2008 | Extension of printing and packaging operations, installation of an 8-colour flexographic printing press. With Matthias Becker-Gröning, the fifth Generation joins the company. | |

| 2007 | Expansion of our coextrusion sector. | |

| 2003 | DIN EN ISO 9001:2000 certification. | |

| 1996 | Three — day celebration of the company's 125th anniversary. | |

| 1994 | DIN EN ISO 9002 certification. Addition of a 6-colour flexographic printing press to the printing division. | |

| 1985 | Expansion of the extrusion hall at the „Stienkamp“ | |

| 1979 | Production of the first HD film from Hoechst Hostalen resin. | |

| 1975 | Closing of jute production sector. | |

| 1973 | Expansion of extrusion hall. | |

| 1972 | Shift from jute to fibre glass production. | |

| 1971 | Celebration of the company's 100th anniversary together with the staff. | |

| 1970 | Installation of the first 6-colour flexographic printing press. | |

| 1965 | Kick — off of polyethylene film production with one extruder, a heat — seal machine and printing press. | |

| 1958 | Production of jute sack with PE inliner. | |

| 1947 | Production is re-assumed under adverse post-war conditions and constantly extended over the following years. | |

| 1904 | Extension of production by adding a jute spinning mill consisting of boiler room and machine room. | |

| 1887 | Upon completion of a factory building and a mechanised jute weaving plant, manual weaving is abandoned. | |

| 1871 | In Rheine — Mesum, Wilhelm Gröning establishes a jute and linen trading business with manual weaving and calendering. | |

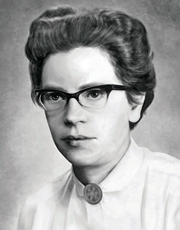

Rudolf Kölling-Gröning (s. 1972) Matthias Becker-Gröning (s. 2008)

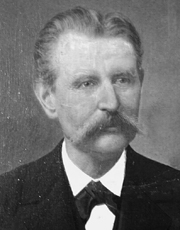

Wilhelm Gröning

Founder of the Company

Wilhelm Gröning jun.

(from 1902)

A. Kölling-Gröning

(from 1947)